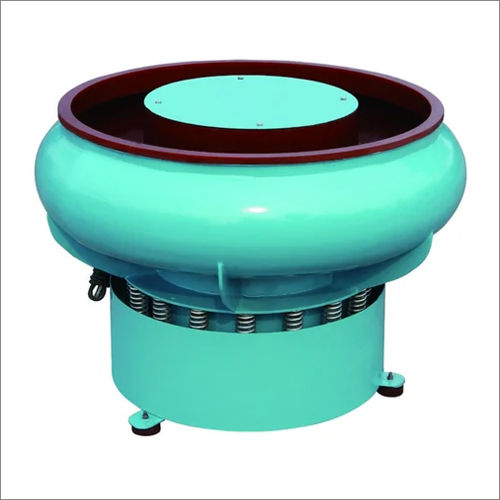

Vibratory Finishing Machine Dome Model

Vibratory Finishing Machine Dome Model Specification

- Usage

- Industrial

- Material

- Mild Steel

- Processing Type

- Standard

- Condition

- New

- Technology

- Vibratory Finishing

- Dimension (L*W*H)

- Variable (customized as per model requirement)

- Power Mode

- Electric

- Voltage

- 220-440 V

- Power Consumption

- 1.5-10 kW (depending on model size)

- Engine Configuration

- Single phase/Three phase available

- Fuel Tank Capacity

- Not applicable (Electric powered)

- Application

- Deburring, Polishing, Surface Finishing, Cleaning for Industrial Components

- Weight

- 200-1200 kg (model dependent)

- Coating Type

- Powder Coated

- Discharge System

- Manual/Automatic discharge

- Bowl Shape

- Dome Model (Circular Bowl)

- Media Capacity

- 50 to 750 Liters

- Water Inlet/Outlet

- Yes, provided for wet finishing process

- Surface Finish

- Smooth, Industrial-grade

- Lining Material

- Polyurethane or Rubber lined bowl

- Timer Function

- Integrated digital timer

- Noise Level

- Below 85 dB

- Working Speed

- 1200-1800 RPM (adjustable)

- Control Panel

- Digital/Analog control options

- Safety Features

- Overload and short-circuit protection

Vibratory Finishing Machine Dome Model Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Vibratory Finishing Machine Dome Model

Ideal Solution for Diverse Industrial Applications

The Vibratory Finishing Machine Dome Model is suitable for mid-to-large scale industrial processing, tackling deburring, polishing, surface finishing, and cleaning. Its versatility makes it perfect for use by manufacturers, metal fabricators, and component suppliers seeking efficient, uniform results. This machine is widely used in automotive, aerospace, and electronic industriesdelivering impeccable finishes on various components and materials. Its adjustable settings and reliable performance support high-volume production environments, making it a top choice for leading industrial operations.

Flexible Purchase, Certifications, and Reliable Delivery

You can secure the Vibratory Finishing Machine Dome Model with a Purchase Order supported by streamlined logistics and drop-off at your designated FOB port. Certified to meet industrial safety and efficiency standards, each machine comes with official documentation for peace of mind. Payment terms are tailored for both bulk and custom orders, ensuring transparent transactions for distributors, traders, and end users. Our team coordinates drop-off and reliable shipping to industrial clients across India, maximizing procurement efficiency.

FAQs of Vibratory Finishing Machine Dome Model:

Q: How does the discharge system in the Dome Model Vibratory Finishing Machine work?

A: The machine offers both manual and automatic discharge systems, allowing users to select the best option for their workflow and efficiency requirements during the finishing process.Q: What types of finishing processes is the Dome Model suitable for?

A: This model excels in deburring, polishing, surface finishing, and cleaning of industrial components, delivering smooth, high-quality surfaces across a wide array of materials.Q: When should I choose polyurethane lining over rubber lining for the bowl?

A: Polyurethane is ideal for intensive use and processing harder parts due to its longer lifespan, while rubber lining is recommended for delicate or softer components that require gentle handling.Q: Where can the Vibratory Finishing Machine Dome Model be installed?

A: It can be installed in any industrial setting equipped with electric power (220-440 V), including manufacturing plants, workshops, and industrial finishing departments.Q: What are the main benefits of using this machine for industrial surface finishing?

A: The machine provides rapid, consistent, and efficient finishing results with low noise, high safety standards, and customizable media capacity, improving overall productivity.Q: How is logistics and delivery managed for large orders?

A: For bulk purchases, logistics are carefully coordinated to ensure timely drop-off at the selected FOB port, with detailed tracking and support throughout shipping and delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibratory Finishing Machine Category

Vibratory Finishing Machine

Minimum Order Quantity : 1 Piece

Coating Type : Powder Coated

Weight : 415 kg

Engine Configuration : Single Phase/Three Phase

Processing Type : Standard

Voltage : 415V

Vibratory Finishing Machine Dome Std Model

Minimum Order Quantity : 1 Piece

Coating Type : Polyurethane Lining

Weight : 300 kg (Approx.)

Engine Configuration : Singlephase or 3phase motor

Processing Type : Standard

Voltage : 415 V

Vibratory Finishing Machine Standard Model

Minimum Order Quantity : 1 Piece

Coating Type : Powder Coated

Weight : Approx. 250 kg

Engine Configuration : Single Phase/Three Phase Motor

Processing Type : Standard

Voltage : 415 V

Deburring Vibratory Finishing Machine

Minimum Order Quantity : 1 Piece

Coating Type : Powder Coated

Weight : 250 to 1200 Kg (as per model)

Engine Configuration : Single Phase / Three Phase

Processing Type : Other, Deburring / Finishing

Voltage : 220415 V

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry