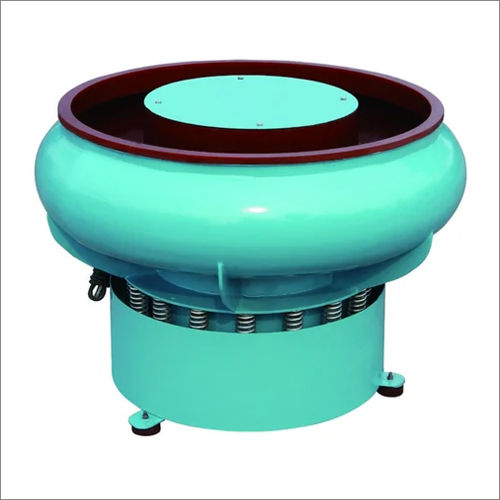

Vibratory Finishing Machine Dome Std Model

Vibratory Finishing Machine Dome Std Model Specification

- Usage

- Industrial

- Material

- Plastic

- Processing Type

- Standard

- Condition

- New

- Technology

- Vibratory Finishing

- Dimension (L*W*H)

- 1100 x 900 x 900 mm (Approx.)

- Power Mode

- Electric

- Voltage

- 415 V

- Power Consumption

- 2.2 kW

- Engine Configuration

- Single-phase or 3-phase motor

- Application

- Industrial Deburring, Polishing, Cleaning

- Weight

- 300 kg (Approx.)

- Coating Type

- Polyurethane Lining

- Vibratory Bowl Capacity

- 100 Liters

- Vibration Frequency

- 50 Hz

- Discharge Method

- Batch or Manual Discharge

- Media Compatibility

- Ceramic, Plastic, Steel Media

- Noise Level

- Below 75 dB

- Surface Treatment

- For Metals, Plastics, Alloys

- Control Panel

- Digital Timer/Manual Control

Vibratory Finishing Machine Dome Std Model Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Vibratory Finishing Machine Dome Std Model

Features and Applications of Vibratory Finishing Machine Dome Std Model

This advanced vibratory finishing machine features an excellent 100-liter capacity vibratory bowl, digital/manual control panel, and operates quietly below 75 dB. Extra features include compatibility with multiple media types-ceramic, plastic, and steel-providing versatility for industrial tasks. Designed for the valiant treatment of metals, plastics, and alloys, its standard processing type is ideal for deburring, polishing, and cleaning. The batch/manual discharge system and polyurethane lining enhance operational longevity and reliability across various industrial applications.

Certifications, Sample Valuation, and FOB Port Details

The Vibratory Finishing Machine Dome Std Model is handed over with high-standard certifications for industrial quality assurance. Sample policy is available for prospective clients, allowing proper valuation before bulk orders. Machines can be handed over at a designated FOB port in India, streamlining international transactions. This approach ensures that clients receive their ordered product with confidence, and the necessary documentation for hassle-free handover and shipping is meticulously provided.

FAQ's of Vibratory Finishing Machine Dome Std Model:

Q: How does the vibratory finishing process work in this model?

A: The process involves placing workpieces and selected media (ceramic, plastic, or steel) in the vibratory bowl. The machine's controlled vibrations gently deburr, clean, and polish the surfaces, providing uniform finishes across metals, plastics, and alloys.Q: What are the main benefits of using the Vibratory Finishing Machine Dome Std Model?

A: Key benefits include efficient surface finishing, reduced noise (below 75 dB), digital/manual control flexibility, and compatibility with various media types, making it excellent for improving productivity in industrial operations.Q: Where can this machine be used most effectively?

A: This vibratory finishing machine finds its best application in industries requiring deburring, cleaning, and polishing of metal, plastic, and alloy components, such as automotive, aerospace, and manufacturing sectors.Q: What kind of control options does the machine offer?

A: The machine comes equipped with both a digital timer and manual control, allowing users to choose between automated, precise cycles or hands-on operation for optimal processing flexibility.Q: What certifications and sample policies are offered before order confirmation?

A: The machine is handed over with necessary industrial certifications. Sample policies are available, allowing users to evaluate performance and value prior to confirming bulk orders.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibratory Finishing Machine Category

Vibratory Finishing Machine Dome Model

Minimum Order Quantity : 1 Piece

Power Consumption : 1.510 kW (depending on model size)

Processing Type : Standard

Power Mode : Electric

Engine Configuration : Single phase/Three phase available

Usage : Industrial

Vibratory Finishing Machine Bump Model

Minimum Order Quantity : 1 Piece

Power Consumption : 2.2 kW

Processing Type : Standard

Power Mode : Electric

Engine Configuration : Direct Drive Motor

Usage : Industrial

Vibratory Finishing Machine Standard Model

Minimum Order Quantity : 1 Piece

Power Consumption : 2 HP

Processing Type : Standard

Power Mode : Electric

Engine Configuration : Single Phase/Three Phase Motor

Usage : Industrial

Vibratory Finishing Machine

Minimum Order Quantity : 1 Piece

Power Consumption : 3 HP

Processing Type : Standard

Power Mode : Electric

Engine Configuration : Single Phase/Three Phase

Usage : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry