Call: 08071931145

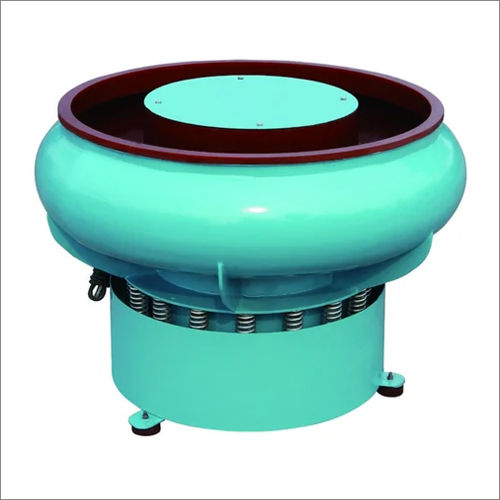

Deburring Vibratory Finishing Machine

MOQ : 1 Piece

Deburring Vibratory Finishing Machine Specification

- Usage

- Industrial

- Material

- Mild Steel

- Processing Type

- Deburring / Finishing

- Condition

- New

- Technology

- Vibratory Finishing

- Dimension (L*W*H)

- Customizable

- Power Mode

- Electric

- Voltage

- 220-415 V

- Power Consumption

- 1-5 kW (depending on model)

- Engine Configuration

- Single Phase / Three Phase

- Application

- Deburring, Polishing, Surface Finishing

- Weight

- 250 to 1200 Kg (as per model)

- Coating Type

- Powder Coated

- Lining Material

- High-Grade Polyurethane

- Safety Features

- Overload Protection, Emergency Stop Switch

- Control System

- Digital / Analog Timer Control

- Operating Temperature Range

- 5°C to 40°C

- Working Speed

- Variable (up to 2800 RPM)

- Bowl Capacity

- 50 to 600 Liters

- Media Compatibility

- Ceramic, Plastic, Steel

- Noise Level

- Below 80 dB

- Surface Finish Quality

- Ra 0.2-0.8 µm

Deburring Vibratory Finishing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Deburring Vibratory Finishing Machine

A Deburring Vibratory Finishing Machine is a type of mass finishing equipment that is used to remove burrs, sharp edges, and other imperfections from the surfaces of parts and components made of various materials, such as metals, plastics, ceramics, and composites. The Deburring Vibratory Finishing Machine works by using vibratory motion to move the parts and finishing media, such as ceramic, plastic, or stainless steel media, within the machine bowl or chamber.

Versatile Media Compatibility

Designed to operate with ceramic, plastic, and steel media, this vibratory finishing machine adapts to various deburring and finishing requirements. Its flexibility makes it suitable for a wide range of industrial components without compromising finish quality.

Precision Surface Finishing

Achieve impressive surface finish quality ranging from Ra 0.20.8 m thanks to the machines high-grade polyurethane lining and advanced vibratory technology. The variable speed control ensures optimal results for different parts and materials.

Enhanced Operational Safety

Safety remains a priority, with features such as overload protection and an emergency stop switch included. These safeguards, combined with a noise level below 80 dB, allow for secure and comfortable operation within industrial environments.

FAQs of Deburring Vibratory Finishing Machine:

Q: How does the Deburring Vibratory Finishing Machine improve surface finish quality?

A: The machine utilizes high-grade polyurethane lining combined with variable speed and precise media selection (ceramic, plastic, or steel) to achieve superior surface finishes, delivering Ra values between 0.2 and 0.8 m for industrial components.Q: What types of media can be used with this vibrating finishing machine?

A: This machine is compatible with ceramic, plastic, and steel media, allowing you to tailor the process to your specific deburring or finishing requirements for various metals and alloys.Q: When should I use this machine for deburring or finishing processes?

A: Utilize the machine during post-production or before final assembly to remove burrs, smooth surfaces, or polish parts, ensuring precise component quality and improved product performance.Q: Where can customized versions of this machine be sourced in India?

A: Customizable models and configurations can be sourced through authorized distributors, suppliers, traders, and wholesalers across India, suited for diverse industrial needs.Q: What safety features are integrated into this machine?

A: The finishing machine includes overload protection and an emergency stop switch, safeguarding operators and equipment during industrial use.Q: How does variable working speed benefit processing?

A: Variable speed functionalityup to 2800 RPMenables operators to adjust the machine for specific materials and finish requirements, optimizing results and efficiency for different tasks.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Vibratory Finishing Machine Category

Vibratory Finishing Machine Dome Model

Minimum Order Quantity : 1 Piece

Weight : 2001200 kg (model dependent)

Coating Type : Powder Coated

Processing Type : Standard

Condition : New

Usage : Industrial

Vibratory Finishing Machine Standard Model

Minimum Order Quantity : 1 Piece

Weight : Approx. 250 kg

Coating Type : Powder Coated

Processing Type : Standard

Condition : New

Usage : Industrial

Vibratory Finishing Machine Reverse Separation Model

Minimum Order Quantity : 1 Piece

Weight : Approx. 450 Kg

Coating Type : Powder Coated

Processing Type : Standard

Condition : New

Usage : Industrial

Vibratory Finishing Machine Dome Std Model

Minimum Order Quantity : 1 Piece

Weight : 300 kg (Approx.)

Coating Type : Polyurethane Lining

Processing Type : Standard

Condition : New

Usage : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry