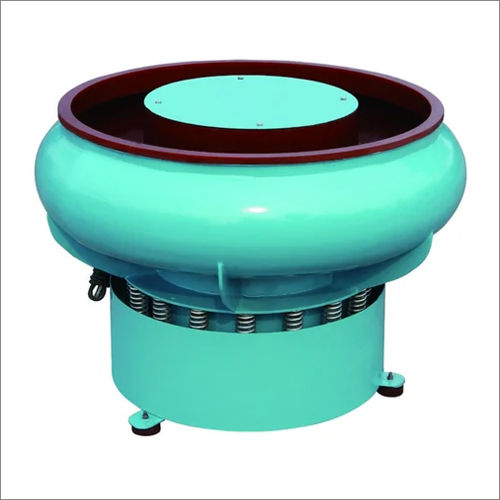

Vibratory Finishing Machine

Vibratory Finishing Machine Specification

- Usage

- Industrial

- Material

- Mild Steel

- Processing Type

- Standard

- Condition

- New

- Technology

- Vibratory Finishing

- Dimension (L*W*H)

- 1150mm x 900mm x 950mm

- Power Mode

- Electric

- Voltage

- 415V

- Power Consumption

- 3 HP

- Engine Configuration

- Single Phase/Three Phase

- Application

- Industrial finishing, deburring, polishing of metal parts

- Weight

- 415 kg

- Coating Type

- Powder Coated

- Control System

- Panel Mounted Switches

- Surface Finish Quality

- Up to Ra 0.2 m

- Separator Type

- Manual or Automatic

- Drive Mechanism

- Vibration Motor Drive

- Maintenance

- Low Maintenance Design

- Media Type Supported

- Ceramic, Plastic, Steel, Corn Cob

- Drain Valve Size

- 1 inch

- Noise Level

- Below 80 dB

- Cycle Time

- Adjustable (30 to 120 minutes)

- Bowl Capacity

- 150 liters

Vibratory Finishing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Vibratory Finishing Machine

Precise Industrial Finishing

Experience superior surface treatment with the vibratory finishing machine engineered for industrial deburring and polishing. Its adjustable cycle time and support for various media types enable customization for a wide range of components. With a 150-liter bowl capacity and a robust build, this machine is suitable for heavy-duty continuous operations, providing uniform results every time.

Low Noise Operation & Efficient Design

Operate efficiently with noise levels maintained below 80 dB, offering a more comfortable workplace environment. The low-maintenance design and durable powder-coated mild steel construction ensure longevity and reliability, reducing downtime while enhancing productivity for industrial suppliers and manufacturers.

FAQs of Vibratory Finishing Machine:

Q: How does the vibratory finishing machine operate?

A: The machine uses a vibration motor drive to agitate media and metal parts in a 150-liter bowl, facilitating effective deburring, polishing, and finishing. Cycle times are adjustable between 30 and 120 minutes, and operation is controlled via panel-mounted switches.Q: What types of finishing media can be used with this machine?

A: This machine supports a range of media such as ceramic, plastic, steel, and corn cob, allowing customization for different materials and surface finish requirements.Q: When should I use the manual or automatic separator feature?

A: The separator type (manual or automatic) is chosen based on production volume and operator preference. Automatic separators save labor in high-volume processes, while manual ones are suitable for smaller, more controlled batches.Q: Where is this machine best utilized?

A: Designed for industrial environments, this machine is ideal for use in manufacturing units, metalworking shops, and supplier facilities that require efficient and consistent part finishing, deburring, or polishing.Q: What are the benefits of using this vibratory finishing machine?

A: This machine delivers a high surface finish quality (up to Ra 0.2 m), minimizes maintenance, ensures quiet operation, and offers adjustable processing tailored to various workpieces, helping improve overall productivity and work environment.Q: What maintenance is required for optimal machine performance?

A: Routine maintenance is minimal, mainly involving regular checks of the vibration motor, cleaning of the bowl, inspection of the drain valve, and ensuring the control switches are functioning properly.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibratory Finishing Machine Category

Vibratory Finishing Machine Dome Model

Minimum Order Quantity : 1 Piece

Power Consumption : 1.510 kW (depending on model size)

Application : Deburring, Polishing, Surface Finishing, Cleaning for Industrial Components

Technology : Other, Vibratory Finishing

Dimension (L*W*H) : Variable (customized as per model requirement)

Processing Type : Standard

Vibratory Finishing Machine Dome Std Model

Minimum Order Quantity : 1 Piece

Power Consumption : 2.2 kW

Application : Industrial Deburring, Polishing, Cleaning

Technology : Other, Vibratory Finishing

Dimension (L*W*H) : 1100 x 900 x 900 mm (Approx.)

Processing Type : Standard

Vibratory Finishing Machine HP Model

Minimum Order Quantity : 1 Piece

Power Consumption : 3 HP

Application : Deburring, Polishing, Descaling, Surface Finishing

Technology : Other, Vibratory

Dimension (L*W*H) : 950 x 950 x 950 mm

Processing Type : Standard

Vibratory Finishing Machine Bump Model

Minimum Order Quantity : 1 Piece

Power Consumption : 2.2 kW

Application : Surface Finishing, Deburring, Polishing

Technology : Other, Vibratory Finishing

Dimension (L*W*H) : 1170 x 1010 x 900 mm

Processing Type : Standard

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry