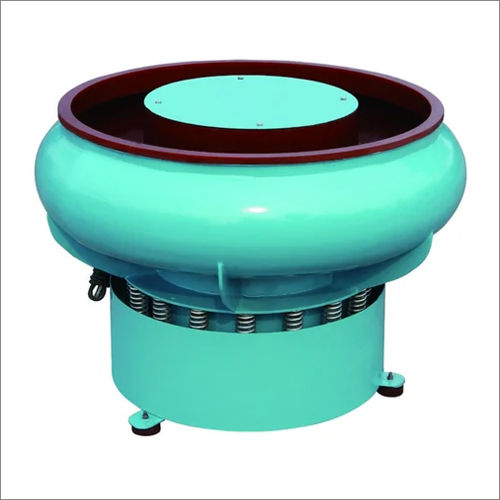

Vibratory Finishing Machine Reverse Separation Model

Vibratory Finishing Machine Reverse Separation Model Specification

- Usage

- Industrial

- Material

- Mild Steel

- Processing Type

- Standard

- Condition

- New

- Technology

- Reverse Separation Vibratory

- Dimension (L*W*H)

- 1500 mm x 900 mm x 800 mm

- Power Mode

- Electric

- Voltage

- 415 V

- Power Consumption

- 3.7 kW

- Engine Configuration

- Single Phase Motor

- Application

- Surface Finishing and Deburring of Metal Parts

- Weight

- Approx. 450 Kg

- Coating Type

- Powder Coated

- Vibration Type

- Rotary/Eccentric

- Control Panel

- Digital

- Separation Mechanism

- Automatic Reverse Separation

- Finish Quality

- Consistent, Uniform

- Cycle Timer

- Programmable

- Noise Level

- <75 dB

- Number of Separators

- 1

- Drum Material

- High-grade Polyurethane Lining

- Bowl Capacity

- 250 Litres

Vibratory Finishing Machine Reverse Separation Model Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Vibratory Finishing Machine Reverse Separation Model

Efficient Reverse Separation Technology

The automatic reverse separation mechanism maximizes the efficiency of media and parts separation during the finishing process. This technology reduces manual intervention and offers reliable throughput for both surface finishing and deburring applications.

Durable Construction and Consistent Finish

Built with high-quality mild steel and protected by a powder-coated finish, this machine guarantees longevity in demanding industrial environments. The bowl is lined with high-grade polyurethane, ensuring consistent performance and protecting parts during processing.

User-Friendly Digital Controls

The digital control panel and programmable cycle timer streamline operations, making it simple to manage and monitor the finishing process. These controls enhance productivity and allow precise customization for different metal parts.

FAQs of Vibratory Finishing Machine Reverse Separation Model:

Q: How does the automatic reverse separation mechanism work in this machine?

A: The automatic reverse separation mechanism efficiently separates finished parts from media by reversing the vibration direction, ensuring a quick and consistent extracting process without manual sorting.Q: What are the key benefits of using a vibratory finishing machine with high-grade polyurethane lining?

A: High-grade polyurethane lining provides superior abrasion resistance, reduces media wear, and protects metal parts from surface damage, resulting in uniform finishing and extended machine lifespan.Q: When is it recommended to utilize the programmable cycle timer feature?

A: Use the programmable cycle timer when you need precise control over processing durations, such as for different part sizes or varying finishing requirements, to optimize throughput and consistency.Q: Where can this vibratory finishing machine be installed for industrial use?

A: This machine can be installed in industrial settings like factories, workshops, or production lines, especially where surface finishing or deburring of metal parts is a constant requirement.Q: What is the process for starting and operating the machine via its digital control panel?

A: To operate the machine, simply select or program the desired cycle on the digital control panel, adjust settings as needed for your application, and initiate the process. The machine will manage the cycle automatically.Q: What type of vibration is used and how does it affect finish quality?

A: The machine employs a rotary/eccentric vibration type, which ensures uniform and consistent finishing by evenly distributing vibratory energy throughout the bowl, minimizing processing variability.Q: What makes this model suitable for industrial distributors and wholesalers in India?

A: Its reliable electric power mode, robust mild steel build, advanced technology, and ease of operation make it an ideal solution for high-volume, industrial finishing requirements commonly encountered by distributors and wholesalers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibratory Finishing Machine Category

Vibratory Finishing Machine Dome Model

Minimum Order Quantity : 1 Piece

Coating Type : Powder Coated

Dimension (L*W*H) : Variable (customized as per model requirement)

Power Consumption : 1.510 kW (depending on model size)

Power Mode : Electric

Technology : Other, Vibratory Finishing

Vibratory Finishing Machine Bump Model

Minimum Order Quantity : 1 Piece

Coating Type : Powder Coated

Dimension (L*W*H) : 1170 x 1010 x 900 mm

Power Consumption : 2.2 kW

Power Mode : Electric

Technology : Other, Vibratory Finishing

Vibratory Finishing Machine Dome Std Model

Minimum Order Quantity : 1 Piece

Coating Type : Polyurethane Lining

Dimension (L*W*H) : 1100 x 900 x 900 mm (Approx.)

Power Consumption : 2.2 kW

Power Mode : Electric

Technology : Other, Vibratory Finishing

Vibratory Finishing Machine Standard Model

Minimum Order Quantity : 1 Piece

Coating Type : Powder Coated

Dimension (L*W*H) : 620x620x900 mm

Power Consumption : 2 HP

Power Mode : Electric

Technology : Other, Vibratory Finishing

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry