Call: 08071931145

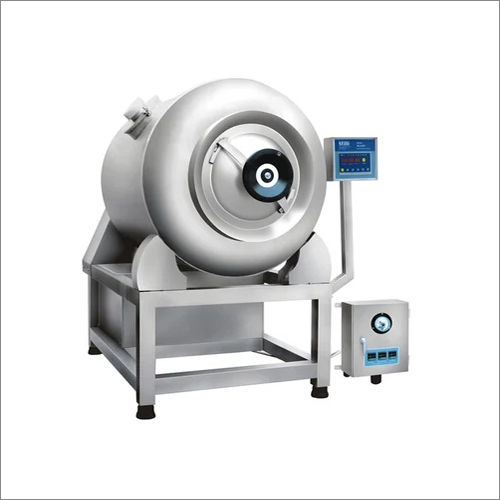

Rectangular Tub Vibrator

MOQ : 1 Piece

Rectangular Tub Vibrator Specification

- Control Type

- Automatic / Semi-Automatic options available

- Material

- Industrial-grade Steel

- Machine Type

- Rectangular Tub Vibrator

- Suitable Media Types

- Ceramic, Plastic, Stainless Steel, Corn Cob

- Application

- Deburring, Polishing and Cleaning of Metal Parts

- Vibration Mode

- Multi-directional

- Maintenance

- Easy to maintain with accessible components

- Safety Features

- Overload and Emergency Stop functions

- Inner Lining Material

- High Abrasion-Resistant Polymer

- Noise Level

- Low

Rectangular Tub Vibrator Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Rectangular Tub Vibrator

A Rectangular Tub Vibrator is a type of vibratory finishing machine used for deburring, polishing, and finishing small to medium-sized parts. As the name suggests, it consists of a rectangular tub that vibrates at high frequency, causing the parts and media inside to move in a circular motion, resulting in efficient and consistent finishing. Rectangular Tub Vibrator is commonly used in various industries, including automotive, aerospace, and medical, to finish parts made from metals, plastics, and ceramics.

Precision Finishing for Metal Parts

The Rectangular Tub Vibrator offers a reliable solution for enhancing the surface quality of metal components. Its multi-directional vibration ensures even processing, making it suitable for deburring, polishing, and cleaning tasks in various industrial settings. The rugged build guarantees longevity and consistent output.

Versatile Media Compatibility

Engineered for maximum flexibility, this machine accommodates a variety of media types, including ceramic, plastic, stainless steel, and corn cob. This versatility enables distributors and suppliers to cater to multiple finishing requirements across different metalworking industries.

Advanced Control and Safety Features

Choose between automatic or semi-automatic operation to suit your workflow. The machine's built-in overload and emergency stop functions offer peace of mind, ensuring safe operation for users while protecting machinery and processed components.

FAQ's of Rectangular Tub Vibrator:

Q: How does the multi-directional vibration improve cleaning and polishing results?

A: The multi-directional vibration mechanism ensures consistent motion throughout the tub, leading to thorough deburring, polishing, and cleaning of metal parts from all angles. This enhances surface finish and evenly processes components, regardless of their shape.Q: What types of industries benefit most from a Rectangular Tub Vibrator?

A: Industries involved in metalworking, including automotive, aerospace, and fabrication, greatly benefit from this machine for efficient deburring and polishing of components. Distributors, suppliers, and traders serving these sectors also find it valuable for bulk processing needs.Q: When is it best to use automatic versus semi-automatic controls?

A: Automatic control is ideal for high-volume, consistent processing where minimal human intervention is required, optimizing efficiency. Semi-automatic mode is suitable for jobs needing more customization or manual oversight, offering flexibility for varied batch sizes or specialized tasks.Q: Where can the Rectangular Tub Vibrator be installed for optimal operation?

A: For optimal performance, install the machine in a well-ventilated, stable industrial workspace with easy access to maintenance. Ensure it's positioned near power sources and in proximity to other processing equipment for smooth workflow integration.Q: What is the maintenance process for this machine?

A: The Rectangular Tub Vibrator is designed for easy maintenance, with accessible components that facilitate straightforward inspection, cleaning, and replacement as needed. Regular checks for wear and maintaining the abrasion-resistant polymer lining ensure sustained performance.Q: How do the safety features on this machine protect users and equipment?

A: The built-in overload protection prevents damage from excessive loads, while the emergency stop function allows users to quickly halt operation in case of any irregularity, reducing the risk of injury or damage to both the machinery and processed parts.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry