Call: 08071931145

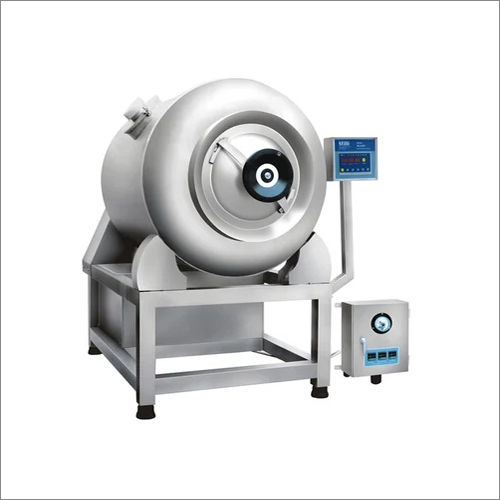

Centrifugal Barrel Finishing Machine

MOQ : 1 Piece

Centrifugal Barrel Finishing Machine Specification

- Machine Type

- Centrifugal Barrel Finishing Machine

- Operation

- High-Efficiency Surface Finishing

- Safety Features

- Interlocked Door, Emergency Stop Button

- Process Speed

- Adjustable depending on workpiece

- Barrel Rotation Speed

- Up to 300 RPM (variable)

- Suitable For

- Steel, Alloys, Ceramics, Plastic Components

- Dimensions

- Customized per Model

- Weight

- Depends on Barrel Capacity

- Barrel Material

- Stainless Steel / Polyurethane Lining

- Noise Level

- Low-noise Operation

- Finishing Media Type

- Ceramic, Plastic, Steel, Organic media

- Control System

- Electronic and Manual Controls

- Typical Applications

- Deburring, Polishing, Cleaning, Surface Smoothing

Centrifugal Barrel Finishing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Centrifugal Barrel Finishing Machine

A Centrifugal Barrel Finishing Machine is a type of mass finishing equipment used to polish and deburr small to medium-sized parts. It consists of a rotating barrel that is mounted on a spindle and driven by a motor. The barrel contains a set of four individual barrels that rotate in the opposite direction of the main barrel. The centrifugal force generated by the rotation of the Centrifugal Barrel Finishing Machine causes the parts and abrasive media inside to move in a circular motion.

Efficient Surface Finishing Technology

Harness advanced centrifugal force with this barrel finishing machine for rapid, consistent deburring, polishing, and cleaning. Its adjustable speed and multiple media options deliver tailored surface results for various materials including steel, alloys, ceramics, and plastics.

Robust Construction and Safety

Stainless steel barrels lined with polyurethane optimize performance and longevity. The machine incorporates interlocked doors and emergency stop controls for heightened safety during operation, ensuring peace of mind for operators and production managers.

Customizable Output for Industrial Needs

Designed to accommodate differing workpiece sizes and finishing requirements, the machines dimensions and barrel capacities are customized to suit specific production scales, making it a versatile choice across industries.

FAQs of Centrifugal Barrel Finishing Machine:

Q: How does the centrifugal barrel finishing machine enhance surface finishing efficiency?

A: By utilizing centrifugal force and adjustable barrel speeds, the machine accelerates the movement of finishing media across workpieces, resulting in faster and more uniform deburring, polishing, and smoothing compared to conventional methods.Q: What types of materials can be processed using this machine?

A: This finishing machine is suitable for steel, alloy components, ceramics, and various plastics, making it highly versatile for manufacturers handling diverse workpiece materials.Q: When should I use ceramic, plastic, steel, or organic finishing media?

A: Media selection depends on the desired surface finish and the material of your workpiece. Ceramic media is ideal for aggressive deburring, plastic media suits gentle polishing, steel is used for tough metals, and organic media works well for delicate surfaces.Q: Where are centrifugal barrel finishing machines commonly applied?

A: They are widely used in automotive, aerospace, electronics, and precision engineering industries, mainly for deburring, polishing, cleaning, and improving the surface quality of components.Q: How does the control system improve operational flexibility?

A: The machine features electronic and manual controls, allowing users to precisely adjust process speed, barrel rotation, and other parameters for optimal finishing results and adaptability to different job requirements.Q: What safety features protect operators during machine use?

A: Safety is ensured through interlocked doors that prevent accidental opening during operation and emergency stop buttons that allow immediate shutdown in case of abnormalities.Q: What are the main benefits of using a centrifugal barrel finishing machine from an Indian distributor or supplier?

A: Purchasing from Indian distributors ensures access to customizable machine models, reliable after-sales support, and efficient fulfillment tailored to domestic industrial requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry